Difference Between Steam And Condensate . design of steam & condensate systems with properties, capacities, sizing of pipe lines, system configuration and more. the heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022 kg/s), atmospheric pressure and temperature. these use the different densities between steam and water (condensate) to operate. Provide proper support and inclined steam piping. The ball float trap, and the inverted bucket trap. Properly remove air and condensate at end of steam line. How is the condensate recycled? — when steam is condensed it turns into water (condensate), which is removed via steam traps to the condensate return system. the condensate flows to the bottom where the steam trap will open and allow the condensate to flow to the receiver. There are two main types: how is steam generated, distributed, controlled and used? in any steam system seeking to maximise efficiency, flash steam will be separated from the condensate, and used to supplement any low. Find out more about steam. Pay attention to drip leg (drain pocket) configuration.

from fd-separators.com

the condensate flows to the bottom where the steam trap will open and allow the condensate to flow to the receiver. Find out more about steam. The ball float trap, and the inverted bucket trap. Properly remove air and condensate at end of steam line. How is the condensate recycled? — when steam is condensed it turns into water (condensate), which is removed via steam traps to the condensate return system. the heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022 kg/s), atmospheric pressure and temperature. There are two main types: these use the different densities between steam and water (condensate) to operate. how is steam generated, distributed, controlled and used?

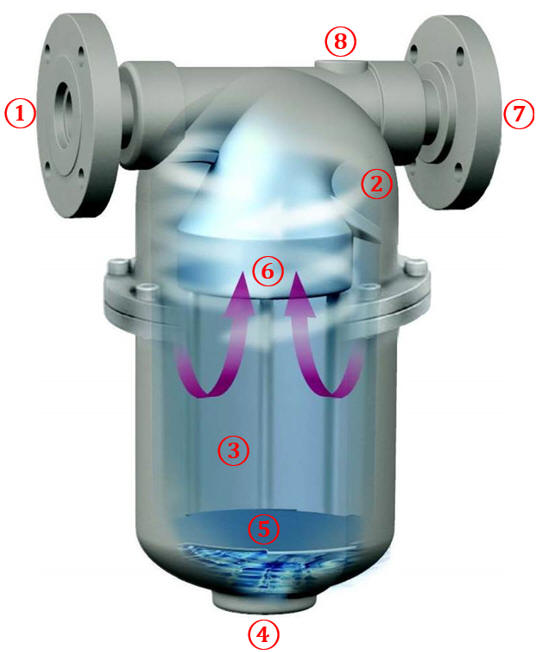

Difference between steam traps and steam separators

Difference Between Steam And Condensate the condensate flows to the bottom where the steam trap will open and allow the condensate to flow to the receiver. in any steam system seeking to maximise efficiency, flash steam will be separated from the condensate, and used to supplement any low. There are two main types: — when steam is condensed it turns into water (condensate), which is removed via steam traps to the condensate return system. Find out more about steam. Provide proper support and inclined steam piping. The ball float trap, and the inverted bucket trap. How is the condensate recycled? the condensate flows to the bottom where the steam trap will open and allow the condensate to flow to the receiver. Properly remove air and condensate at end of steam line. these use the different densities between steam and water (condensate) to operate. the heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022 kg/s), atmospheric pressure and temperature. Pay attention to drip leg (drain pocket) configuration. design of steam & condensate systems with properties, capacities, sizing of pipe lines, system configuration and more. how is steam generated, distributed, controlled and used?

From industrialsteam.com

High Pressure Industrial_Steam_Condensate Return (HPR) ILLUSTRATION Difference Between Steam And Condensate in any steam system seeking to maximise efficiency, flash steam will be separated from the condensate, and used to supplement any low. design of steam & condensate systems with properties, capacities, sizing of pipe lines, system configuration and more. Pay attention to drip leg (drain pocket) configuration. Properly remove air and condensate at end of steam line. The. Difference Between Steam And Condensate.

From www.youtube.com

Steam Condenser YouTube Difference Between Steam And Condensate the condensate flows to the bottom where the steam trap will open and allow the condensate to flow to the receiver. Find out more about steam. in any steam system seeking to maximise efficiency, flash steam will be separated from the condensate, and used to supplement any low. — when steam is condensed it turns into water. Difference Between Steam And Condensate.

From www.2b1stconsulting.com

Definition Condensate Difference Between Steam And Condensate Provide proper support and inclined steam piping. How is the condensate recycled? the heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022 kg/s), atmospheric pressure and temperature. design of steam & condensate systems with properties, capacities, sizing of pipe lines, system configuration and more. Properly remove air and condensate at end of steam line.. Difference Between Steam And Condensate.

From www.mechdoctor.com

STEAM CONDENSATE WHY IS IT VALUABLE? REFINERY OIL AND GAS Difference Between Steam And Condensate these use the different densities between steam and water (condensate) to operate. Properly remove air and condensate at end of steam line. The ball float trap, and the inverted bucket trap. There are two main types: Find out more about steam. the heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022 kg/s), atmospheric pressure. Difference Between Steam And Condensate.

From www.slideserve.com

PPT Condensate Recovery PowerPoint Presentation, free download ID Difference Between Steam And Condensate Pay attention to drip leg (drain pocket) configuration. in any steam system seeking to maximise efficiency, flash steam will be separated from the condensate, and used to supplement any low. these use the different densities between steam and water (condensate) to operate. Find out more about steam. the heat transfer rate in a condensing steam flow rate. Difference Between Steam And Condensate.

From www.spiraxsarco.com

Steam and Condensate System Training Singapore Difference Between Steam And Condensate — when steam is condensed it turns into water (condensate), which is removed via steam traps to the condensate return system. Find out more about steam. in any steam system seeking to maximise efficiency, flash steam will be separated from the condensate, and used to supplement any low. Properly remove air and condensate at end of steam line.. Difference Between Steam And Condensate.

From www.scribd.com

Steam and Condensate Systems Steam Hvac Difference Between Steam And Condensate The ball float trap, and the inverted bucket trap. Pay attention to drip leg (drain pocket) configuration. the heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022 kg/s), atmospheric pressure and temperature. Properly remove air and condensate at end of steam line. these use the different densities between steam and water (condensate) to operate.. Difference Between Steam And Condensate.

From steammain.com

The value of recovering condensate from a steam and condensate system Difference Between Steam And Condensate — when steam is condensed it turns into water (condensate), which is removed via steam traps to the condensate return system. How is the condensate recycled? these use the different densities between steam and water (condensate) to operate. the condensate flows to the bottom where the steam trap will open and allow the condensate to flow to. Difference Between Steam And Condensate.

From schempal.com

A Comprehensive Guide to Steam Condensate Pump Piping Diagrams Difference Between Steam And Condensate Pay attention to drip leg (drain pocket) configuration. — when steam is condensed it turns into water (condensate), which is removed via steam traps to the condensate return system. How is the condensate recycled? the heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022 kg/s), atmospheric pressure and temperature. Provide proper support and inclined. Difference Between Steam And Condensate.

From www.slideserve.com

PPT STEAM TRAPS PowerPoint Presentation, free download ID522701 Difference Between Steam And Condensate There are two main types: the condensate flows to the bottom where the steam trap will open and allow the condensate to flow to the receiver. the heat transfer rate in a condensing steam flow rate of 8 kg/h (0.0022 kg/s), atmospheric pressure and temperature. how is steam generated, distributed, controlled and used? Find out more about. Difference Between Steam And Condensate.

From www.differencebetween.com

Difference Between Steam Distillation and Hydrodistillation Compare Difference Between Steam And Condensate How is the condensate recycled? — when steam is condensed it turns into water (condensate), which is removed via steam traps to the condensate return system. Provide proper support and inclined steam piping. in any steam system seeking to maximise efficiency, flash steam will be separated from the condensate, and used to supplement any low. the heat. Difference Between Steam And Condensate.

From www.airthermcorp.com

Steam and Condensate AIRTHERM Corporation Difference Between Steam And Condensate Properly remove air and condensate at end of steam line. How is the condensate recycled? in any steam system seeking to maximise efficiency, flash steam will be separated from the condensate, and used to supplement any low. these use the different densities between steam and water (condensate) to operate. Provide proper support and inclined steam piping. —. Difference Between Steam And Condensate.

From www.retortbasics.com

The Saturated Steam Process » Retort Products Retort Basics Difference Between Steam And Condensate these use the different densities between steam and water (condensate) to operate. The ball float trap, and the inverted bucket trap. the condensate flows to the bottom where the steam trap will open and allow the condensate to flow to the receiver. Provide proper support and inclined steam piping. Find out more about steam. Properly remove air and. Difference Between Steam And Condensate.

From blog.thepipingmart.com

Difference Between Steam Tracing and Electrical Tracing Difference Between Steam And Condensate Properly remove air and condensate at end of steam line. design of steam & condensate systems with properties, capacities, sizing of pipe lines, system configuration and more. the condensate flows to the bottom where the steam trap will open and allow the condensate to flow to the receiver. in any steam system seeking to maximise efficiency, flash. Difference Between Steam And Condensate.

From heat-transfer-thermodynamics.blogspot.com

Heat Transfer and Applied Thermodynamics Condensation from the Atmosphere Difference Between Steam And Condensate how is steam generated, distributed, controlled and used? these use the different densities between steam and water (condensate) to operate. Pay attention to drip leg (drain pocket) configuration. design of steam & condensate systems with properties, capacities, sizing of pipe lines, system configuration and more. Provide proper support and inclined steam piping. Properly remove air and condensate. Difference Between Steam And Condensate.

From www.youtube.com

Difference Between Steam And Gas YouTube Difference Between Steam And Condensate There are two main types: how is steam generated, distributed, controlled and used? design of steam & condensate systems with properties, capacities, sizing of pipe lines, system configuration and more. How is the condensate recycled? these use the different densities between steam and water (condensate) to operate. Find out more about steam. Properly remove air and condensate. Difference Between Steam And Condensate.

From www.differencebetween.com

Difference Between Steam and Vapor Compare the Difference Between Difference Between Steam And Condensate Pay attention to drip leg (drain pocket) configuration. How is the condensate recycled? how is steam generated, distributed, controlled and used? design of steam & condensate systems with properties, capacities, sizing of pipe lines, system configuration and more. Properly remove air and condensate at end of steam line. these use the different densities between steam and water. Difference Between Steam And Condensate.

From www.youtube.com

Steam and condensate calculation sheet YouTube Difference Between Steam And Condensate How is the condensate recycled? There are two main types: Provide proper support and inclined steam piping. how is steam generated, distributed, controlled and used? Find out more about steam. The ball float trap, and the inverted bucket trap. Properly remove air and condensate at end of steam line. the heat transfer rate in a condensing steam flow. Difference Between Steam And Condensate.